Mine sieving mesh is a metal mesh structure used for sieving and filtering. It is applied in sieving, filtering, dewatering, and de-sludging operations. It offers high strength, rigidity, and load-bearing capacity, and can be made into rigid sieving and filtering devices of various shapes.

Pipe Surfaces

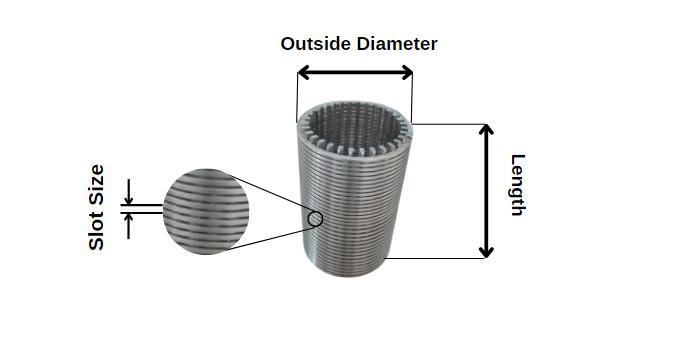

We offer wedge wire screen tubes with 2 different tube surfaces: normal type, and perfect round type. Cross-section of a regular wedge wire screen tube is a square polygon that is almost circular, and the wedge filaments between the adjacent support rods are straight. Perfect round wedge wire screen tubes have a perfectly round cross-section, and a wider filtration range, and better filtration accuracy than normal type. Normal wedge wire screen tubes are more economical for coarse screening.

Low carbon steel wire, high manganese steel wire, stainless steel wire.

Widely used in mining, coal, petroleum, fertilizer, grain, salt, environmental protection, and other industries.

Mine sieving mesh is a new product in the wire mesh industry. It is a metal mesh structure element used for sieving and filtering. Mine sieving mesh includes polyurethane sieving mesh, manganese steel mine sieving mesh, and stainless steel mine sieving mesh. The following introduction focuses on metal materials.

High sieving efficiency, wear-resistant, corrosion-resistant, anti-slip, vibration-resistant, strong elasticity, toughness, and no clinching. The wire cross-section is trapezoidal. The gaps are narrow at the top and wide at the bottom. It is made of stainless steel wire cold-rolled into screening bars, with supporting bars welded by automated mine sieving mesh production equipment, ensuring uniform screen holes, stable welding quality, high opening rate, long service life, high strength, rigidity, and load-bearing capacity, and can be made into rigid sieving and filtering devices of various shapes.

It is a metal mesh structure element used for sieving and filtering, widely applied in various industries for sieving, filtering, dewatering, and de-sludging operations. It offers high strength, rigidity, and load-bearing capacity, and can be fabricated into rigid sieving and filtering devices of various shapes. It is leak-proof, wear-resistant, and corrosion-resistant. The wire cross-section is trapezoidal, with narrow gaps at the top and wide gaps at the bottom.

Flat screen plates, arc screens, polyurethane screen plates, woven original coal sieve strip screen mesh, petroleum filter screens, salt industry screens, centrifuge screen baskets,

filters, stainless steel mesh sleeves.

Used in mining, coal, petroleum, fertilizer, grain, and environmental protection industries for strip screen mesh, petroleum filter screens, and salt industry screens.